CUSTOM PRODUCT EXAMPLES

Mechanical Seals

Mechanical Seals

For maintaining the operating health of fluid-handling equipment that uses centrifugal pumps, integrated mechanical rotary seals are critically important. Specially engineered composite seals with mechanical actuation help keep pumps performing smoothly and efficiently, and when a mechanical seal fails, Utex is the go-to choice for repair and replacement.

In addition to supplying a full line of Utex-branded mechanical seals for use in a variety of applications, we can also perform mechanical seal service work on virtually any ANSI, API, or ISO 2858 pump—just contact us for a free quote.

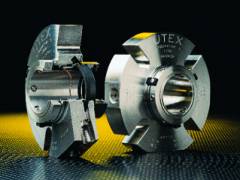

Liberator I

The Liberator I cartridge seal (patented) incorporates advanced seal design features. Using a “ball” drive, the Liberator resists twisting and torsional strains common to pin or key drives. The thin cross-section allows the Liberator I to be used in ANSI pumps without modifications.

This precision-made mechanical seal employs a multi-crested wave spring which is isolated from the product for optimum corrosion resistance. Standard face materials are carbon vs. silicon carbide which together provide the highest PV rating of any face material combination. The rotating seat and spring loaded stationary accept higher shaft speeds, heavier viscosity fluids, and greater misalignment.

Liberator II

The Liberator II cartridge seal (patented) offers all of the design features of the Liberator I. In addition, it features two tangential outlet ports for clockwise or counterclockwise pump rotation. A pumping ring built in as a standard feature provides positive barrier fluid circulation.

The Liberator II is a double hydraulically balanced seal which allows it to be used as a double or tandem seal. In vertical installations, the secondary seal chamber is self-venting to ensure proper lubrication of the secondary sealing faces. The barrier fluid at the secondary seal

is on the O.D. of the sealing faces, which ensures maximum heat dissipation.

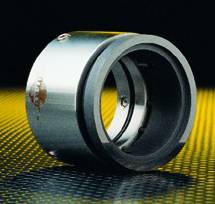

Unilite®

The Unilite is a unique non-metallic mechanical seal that delivers economy and durability all in a proven design. A metal collar insert protects the composite material when the set screws are tightened, making this a uniquely rugged design for the field. And because it uses no setting clips, this full cartridge seal is simpler to install than previous mechanical seals.

Its features include:

- The economy of a non-metallic seal

- Proven polyphenylene sulfide non-metallic composite

- High chemical resistance

- Available with flush on request

- No setting clips required

- Factory repairable

Utex MP

The Utex MP is a straight-line, pressure-balanced seal for handling anything from clean water to crude oil. The design features springs that are isolated from the product to prevent clogging and fatigue. No sliding elastomers are used that could create shaft or sleeve fretting.

Solid carbon faces are used, eliminating the need for shrink fits and allowing easy in-plant repairs. This seal has a slim line design that fits AVS and ANSI pumps. The seal’s integral balance does not require stepped shafts or sleeves and can be used at operating pressures of 0 to 450 psi. Utex MP seals are available through 6″ sizes.

Utex CO

The Utex CO seal is an outside-mounted seal with a unique design ideally suited for most chemical applications. CO seals operate with no wetted metal parts for increased chemical resistance. It is available with Aflas o-rings to handle most chemical applications and temperature ranges.

The springs are isolated from the product to prevent clogging and to further enhance the seal’s chemical resistance. This seal is externally balanced for pressures up to 150 psi and comes standard with a split clamping ring ideal for ceramic shafts. Utex CO seals are available in 1″ through 4″ sizes.

Need more sealing solutions? We'll point you in the right direction.

Engineered Seals

Utex has decades of experience designing and manufacturing mechanical seals for a broad spectrum of industries. Using CAD/CAM technology, we design and manufacture our own

products and maintain a large inventory of standard and custom-designed products.

Our years of experience and engineering expertise give us the know-how to handle pumping problems whether it takes a simple balance modification or an entire custom-engineered seal. This gives our customers the option of ordering high-quality seals for highly specialized applications while maintaining cost-efficient economies.

We have the flexibility to design custom seals and associated parts for high temperature applications, corrosive material service, for high durability operating requirements and for handling all types of fluids. It is a total sealing technology capability that Utex offers.

Save Money Repairing vs. Replacing

Many of our customers are shocked to learn how much money they can save by having Utex repair or replace a faulty mechanical seal instead of buying a complete pump replacement.

Before proceeding with a new pump purchase recommended by the manufacturer, contact us first to determine if a mechanical seal can be repaired or replaced. In most cases, we can quickly restore a hydraulic pump to excellent working condition using better seals than the ones initially included with the OEM equipment.

Need more sealing solutions? We'll point you in the right direction.